We were founded in 1968 and have been providing composite wind blades since 2001. Our knowledge and experience of composite materials and manufacturing originates with our predecessor company, Tillotson Pearson Inc., a leading manufacturer of high-performance sail and powerboats along with a wide range of composite structures used in other industrial applications.

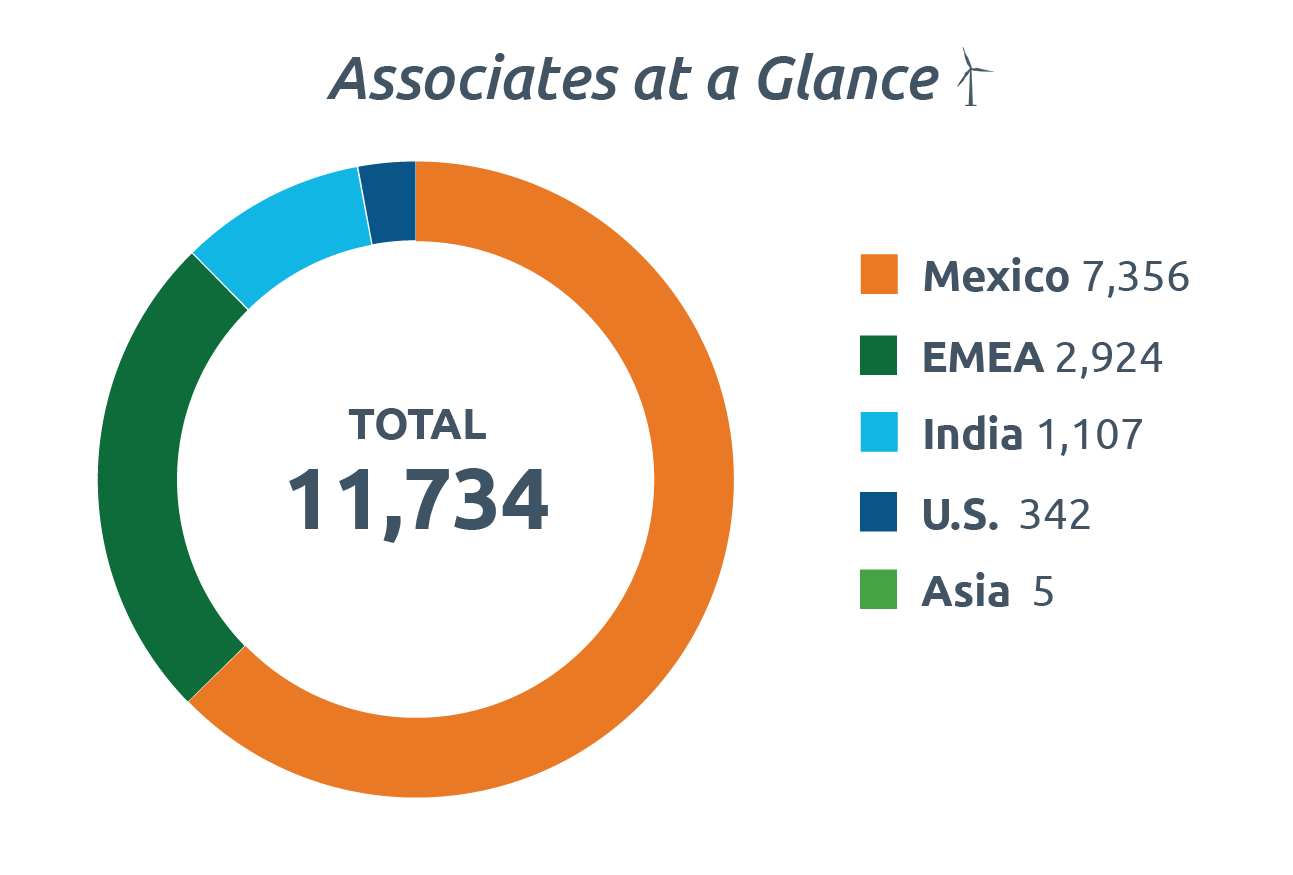

TPI is headquartered in Scottsdale, Arizona and operates factories in the U.S., Mexico, and India. TPI operates additional engineering development centers in Denmark and Germany and global service training centers in the U.S., France, United Kingdom, and Spain.

We are a global company focused on innovative and sustainable solutions to decarbonize and electrify the world. In 2024, we accounted for approximately 27% of all onshore wind blades on a MW-basis globally, excluding China.1 This year we had $1.3 billion in net sales and produced 6,525 wind blades. We are enabling many of the industry’s leading wind turbine original equipment manufacturers (OEMs) to outsource the manufacturing of a larger portion of their wind blades, thus expanding their global wind blade capacity. We manufacture advanced composite wind blades to our customers’ specifications in facilities designed, built, and strategically located either near our customers’ target markets or in low-cost, world-class locations, to minimize total delivered cost. We have leveraged our footprint and thousands of capable associates to build a global team of experienced technicians to provide best-in-class wind blade service capabilities, including preventative services, inspections, repairs, and improvements.

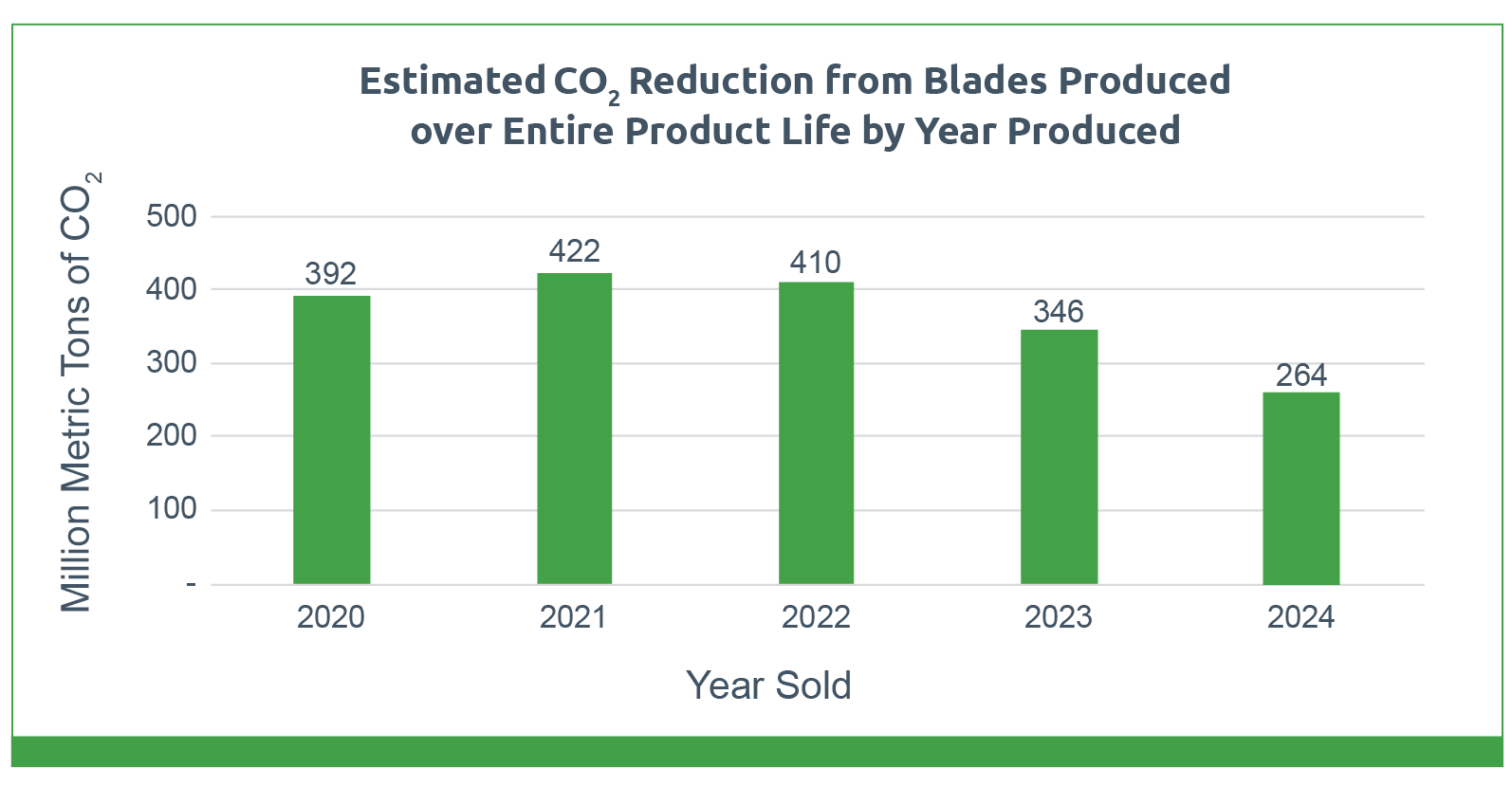

The wind blades we manufacture support the decarbonization of energy production and provide significant reductions in greenhouse gas (GHG) emissions.

The wind blades that we produced in 2024 have the potential to reduce over 264 million metric tons of CO2 over their average 20-year life span.2 This is equivalent to the electricity use of more than 55 million homes in the U.S. for one year.3

TPI’s Mission

To deliver innovative and sustainable solutions to decarbonize and electrify the world by expanding the adoption of renewable energy. We accomplish this by cultivating an inclusive culture that attracts, develops, excites, and retains exceptional talent.

TPI’s Vision

To lead the energy transition through advanced technology and innovative solutions.

TPI’s Core Values

- Safety

- Operational Excellence

- Commitment

- Integrity

- Leadership

1 TPI’s market share based on TPI MW relative to global total onshore MW (excl. China) from Wood Mackenzie, “Global Wind Power Market Outlook Q1 2025.” 2016 and 2019 includes discontinued operations in China.

2 TPI Produced Estimated MWs x 1000 x Total Lifetime Hours x Estimated Turbine Capacity Factor (DOE/IRENA) x IEA emissions factor of 475 g CO2/kW

3 Environmental Protection Agency (EPA). (2024) GHG Equivalencies Calculator