Careful Consideration for Efficient Composite Solutions

Composite material systems are a complex combination of fiber and resin that when properly chosen will yield the highest possible strength and stiffness at the lowest weight. When these materials are laminated to lightweight core, very high bending strength and bending stiffness can be achieved with virtually no significant weight increase. The right choice of materials must include consideration of the structural configuration and externally applied loads as well as environmental conditions and expected service life. It is also critical to consider the manufacturing and fabrication methods as part of the material selection process.

TPI applies this holistic approach to enable optimal performance and cost for your composite product. TPI has over five decades of experience with composite materials, processes and design. In the field of fiber reinforced plastics, we have developed a deep understanding of composite material behavior, from anisotropic elasticity, quasi-static and fatigue strength to manufacturing sciences of processing, fabrication and assembly.

This is particularly important for applications that involve long life under high fatigue loading. The exact knowledge of material behavior and performance are key to the right choice for successful, low-cost operation. Material selection generally includes extensive mechanical testing of coupons to evaluate static strength and stiffness as well as cyclic load testing that feeds structural design. TPI has developed cost-effective testing protocols to inform our generic material models for consistent application in design optimization.

These material models provide consistent methods to quantify the durability of our structural designs to withstand peak operational loads and provide a lifetime of reliable service. The ability to account for underlying material deviations such as fiber distortion, porosity or other imperfections in the material analysis supports generation of allowable manufacturing tolerances while driving affordability. From this insight, our team derives a complete set of design allowables using probabilistic methods for all the materials applied to our structural solutions.

TPI continues to support the advanced materials industry partnering with dozens of reinforcements and resins suppliers to drive innovation and constantly bring new products that improve performance and reduce cost. Related to the life-cycle analysis of the materials we employ, TPI is leading efforts to identify sustainable materials that will present affordable end-of-life options for our composite products. This initiative includes supporting programs to identify paths of material recyclability to protect our environment for today and future generations.

Materials are the primary drivers in system performance and production costs. Let TPI Composites guide you to the most cost effective, environmentally suitable, and structurally efficient composite solution for your next structural application.

Materials

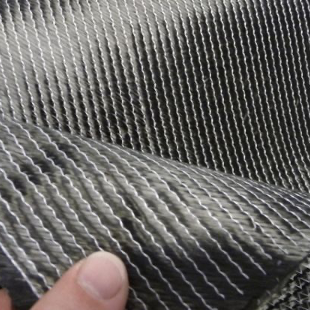

Reinforcements

Glass:

Low-cost high specific strength, modest specific stiffness

Carbon:

High cost but with high specific strength AND stiffness

Others:

Aramids, Basalt etc.

Resins

Epoxies

Vinyl/Poly-ester

“Toughened” Resins:

ETBN/CTBN Reactive Liquid Polymers

Core Shell Rubber

Nano-technologies

Thermoplastics

Core Materials

Foam

Balsa

Honeycomb