Precision Molding and Assembly Systems

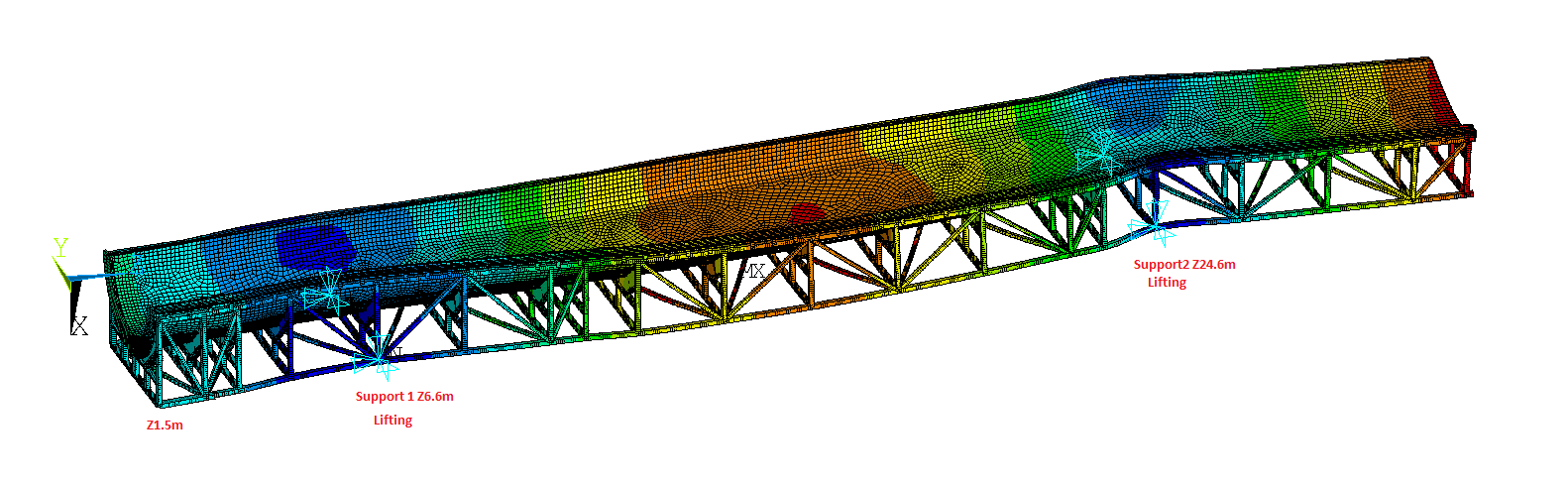

TPI is a world class blade manufacturing operation. As a complete solutions provider for the wind blade industry, we have produced hundreds of precision molding and assembly systems, ranging from 30 meters to over 80 meters in length. These operations began in our tooling technology center in Warren, Rhode Island during the early 2000’s. Our precision molding and assembly systems have been used to build tens of thousands of wind blades worldwide.

Our tooling solutions range from precision wind blade patterns, precision molding and assembly systems, to component handling and quality assurance tools. Our approach takes advantage of modular tooling techniques and integrates advanced design-for-manufacture features. These include laser projection systems, manufacturing process sensors, as well as PLC (programmable logic controller) based control and data acquisition systems. Our technological and production expertise are key factors to our continued competitiveness. TPI tooling is well positioned to serve the wind industry as it requires increasingly bigger blades, demanding and intricate technical specifications, and strict quality control requirements.